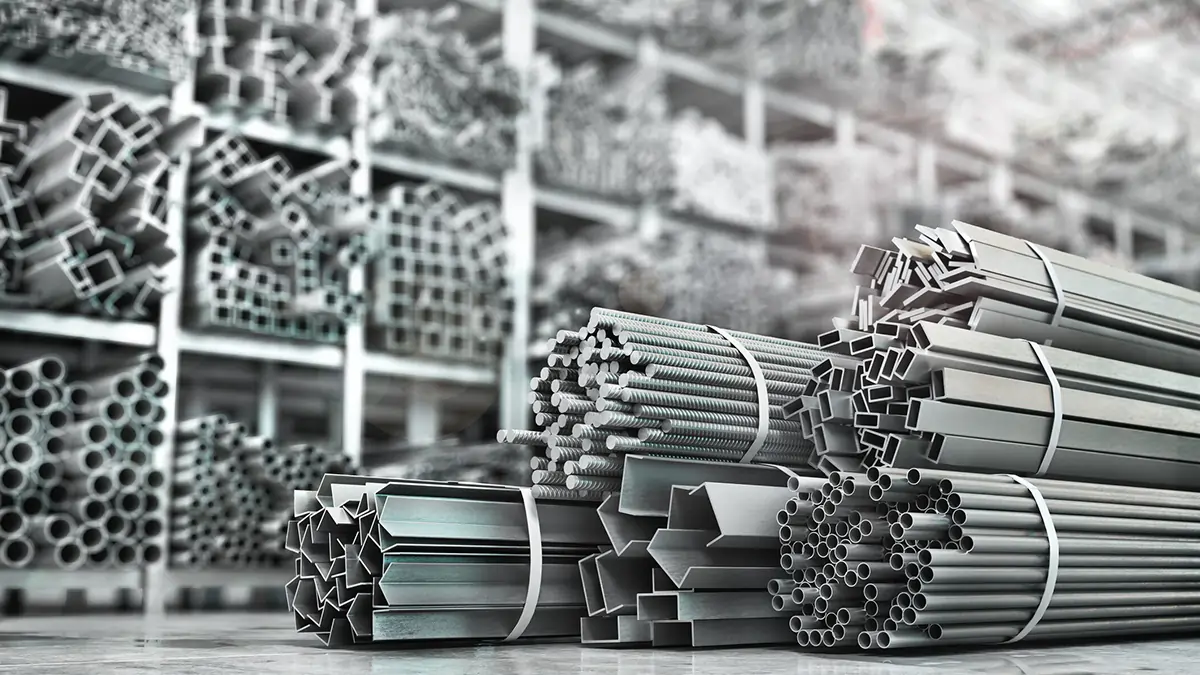

In the vast world of industrial materials, steel continues to dominate due to its strength, durability, and adaptability. Among the most widely used forms of steel in infrastructure and construction are welded steel pipes, including square and rectangular steel pipes. These products are essential across multiple sectors, including construction, transportation, manufacturing, agriculture, energy, and more.

As industries look for reliable, cost-effective, and versatile steel solutions, the demand for welded and shaped steel pipes continues to rise. This article explores the manufacturing process, types, advantages, and global applications of welded steel pipes—especially square and rectangular variants.

What Are Welded Steel Pipes?

Welded steel pipes are produced by rolling a steel plate or coil into a pipe shape and then welding the seam. Unlike seamless pipes, which are made without joints, welded pipes have a visible weld along the length. However, thanks to modern techniques like electric resistance welding (ERW) and submerged arc welding (SAW), these welds are strong and reliable.

Types of Welded Steel Pipes:

-

ERW (Electric Resistance Welded) Pipes: Widely used for precision applications.

-

SSAW (Spiral Submerged Arc Welded) Pipes: Ideal for large-diameter pipelines.

-

LSAW (Longitudinal Submerged Arc Welded) Pipes: Used in energy transmission and structural roles.

Square and Rectangular Steel Pipes: Defined

Square and rectangular steel pipes (also called hollow sections or HSS—hollow structural sections) are specialized welded pipes shaped into square or rectangular profiles. These pipes offer strength and visual appeal, making them ideal for architectural, mechanical, and structural applications.

Common Sizes & Thicknesses:

-

Square Pipes: From 10x10mm to 500x500mm

-

Rectangular Pipes: From 20x10mm to 600x400mm

-

Wall thicknesses can range from 1.0 mm up to 20 mm, depending on structural needs.

Key Advantages of Welded, Square & Rectangular Pipes

🔩 Strength and Durability

Welded steel pipes are incredibly strong and capable of withstanding internal and external pressure, making them ideal for load-bearing applications.

⚙️ Cost-Effective

Compared to seamless pipes, welded pipes are more affordable due to simpler production and lower raw material costs.

🧱 Structural Versatility

Square and rectangular pipes offer uniform geometry, making them easier to work with in structural framing, bridges, supports, and architectural designs.

🔧 Ease of Fabrication

These pipes are easy to cut, weld, and drill, allowing for flexible customization and installation on-site.

🌎 Wide Availability

Welded pipes are available in numerous grades, lengths, thicknesses, and finishes, ensuring suitability for virtually any industry or environment.

Materials and Standards

Most welded steel pipes are made using:

-

Carbon Steel (e.g., ASTM A500, A513)

-

Galvanized Steel (zinc-coated for corrosion resistance)

-

Alloy Steel (for higher performance needs)

-

Stainless Steel (for corrosion-resistance and hygiene)

They follow international standards such as:

-

ASTM A53 / A500 / A554

-

EN 10219 / EN 10210

-

JIS G3444 / G3466

-

IS 4923 (India)

Surface Treatments and Finishes

To enhance appearance and performance, welded pipes are often treated with:

-

Hot-dip galvanizing: Long-lasting rust protection

-

Powder coating or painting: Decorative and functional

-

Oiling or black finish: Prevents corrosion during storage and transit

Applications Across Industries

🏗️ Construction and Infrastructure

-

Structural framing

-

Scaffolding and supports

-

Columns and beams

-

Door and window frames

-

Rooftop structures and shelters

🚛 Automotive and Transportation

-

Trailer frames

-

Bus and truck chassis

-

Protective railings and roll cages

🛢️ Oil & Gas and Utilities

-

Pipeline transportation

-

Casing and tubing

-

Water and gas lines

🧑🏭 Manufacturing and Machinery

-

Conveyor structures

-

Machine frames

-

Storage racks and support arms

🏢 Architectural and Decorative

-

Fencing and railing systems

-

Furniture frames

-

Facade designs and art installations

Welded Pipe Manufacturing Process

1. Material Preparation

Steel coils or plates are unrolled, leveled, and trimmed to desired widths.

2. Forming

The flat steel strip is formed into a cylindrical, square, or rectangular shape using forming rollers.

3. Welding

The edges are heated using electric resistance or submerged arc methods and fused together. The weld bead is often removed or smoothed.

4. Sizing and Shaping

Pipes pass through sizing rolls to ensure accurate dimensions and shape.

5. Heat Treatment and Surface Finish

Stress-relieving and galvanizing processes may be applied depending on the specification.

6. Cutting and Packaging

Pipes are cut to standard or custom lengths, inspected, and prepared for shipping.

China and Global Supply Chain

China is one of the leading producers and exporters of welded square and rectangular steel pipes, offering:

-

Competitive pricing

-

Large production capacity

-

Custom dimensions and coatings

-

Fast international shipping

Manufacturers in India, Turkey, South Korea, and Vietnam are also prominent in global supply, serving industries in North America, Europe, the Middle East, and Africa.

How to Choose the Right Supplier

When sourcing welded or shaped steel pipes, consider:

✅ Certifications (ISO, API, CE, etc.)

✅ Material traceability and testing

✅ Dimensional accuracy and tolerance control

✅ Corrosion protection (galvanizing, painting)

✅ Packaging and export experience

Working with an experienced supplier ensures quality, consistency, and compliance with your project needs.

Conclusion

Welded steel pipes, particularly square and rectangular types, are integral to modern industry thanks to their strength, versatility, and cost-efficiency. Whether used in a commercial building, a highway bridge, or an industrial machine, these pipes provide the backbone for safe and efficient construction.

With growing demand across infrastructure, transportation, and manufacturing, reliable access to high-quality welded pipe products has never been more important. Choosing the right supplier—one who offers precision manufacturing, quality materials, and dependable logistics—can make a significant impact on your project timeline and bottom line.

For industries that require dependable performance with scalable supply, welded steel pipes and hollow structural sections remain an unbeatable choice.