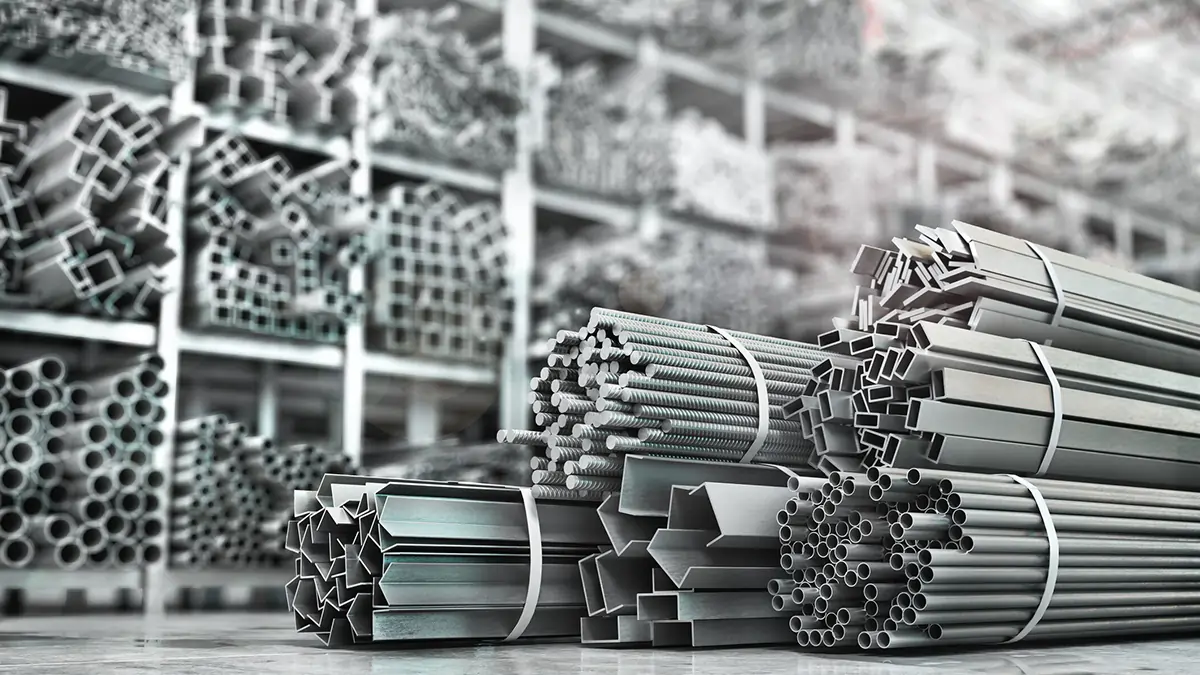

Steel is the backbone of countless industries worldwide — from construction and manufacturing to infrastructure, automotive, and machinery. Among the most essential products in the steel industry are hot-rolled steel strip coils and square and rectangular steel pipes. These products are widely used for their structural integrity, versatility, and adaptability to a wide range of applications.

For buyers, contractors, and suppliers looking for durable and cost-effective steel solutions, understanding the properties, uses, and sourcing options for these materials is critical.

What Are Hot-Rolled Steel Strip Coils?

Hot-rolled steel strip coils are flat steel products that are processed at high temperatures, typically over 1700°F (927°C). This process allows the steel to be shaped and formed easily, making it ideal for structural and mechanical applications. Once cooled, the steel is coiled into large rolls, ready for further processing or direct use.

Key Features:

-

High formability and workability

-

Cost-effective for large-scale applications

-

Excellent weldability

-

Good strength and uniformity

-

Easily machinable and cuttable

Hot-rolled steel coils are commonly used as base material for cold-rolled products, tubes, pipes, automotive frames, and agricultural equipment. They are also used in construction for beams, channels, and steel profiles.

Applications of Hot-Rolled Steel Strip Coils

The versatility of hot-rolled steel strip coils makes them essential in various industries:

-

Construction: Used in the fabrication of I-beams, channels, and structural components for buildings and bridges.

-

Automotive: Applied in frames, wheel rims, chassis, and underbody parts.

-

Manufacturing: Base material for steel tubes, flat bars, and re-rolling mills.

-

Machinery: Employed in the production of industrial and agricultural machines due to its strength and malleability.

-

Energy & Infrastructure: Used for wind turbine parts, support structures, and general infrastructure.

Square and Rectangular Steel Pipes

Square and rectangular steel pipes, also referred to as hollow structural sections (HSS), are long, hollow-shaped metal sections with either square or rectangular cross-sections. These pipes are typically manufactured using hot-rolled or cold-rolled steel and welded to create a strong, uniform shape.

Advantages:

-

High structural strength

-

Lightweight compared to solid steel sections

-

Uniform thickness and dimensions

-

Excellent for welding, bolting, and fabrication

-

Saves space and materials in construction

Square and rectangular steel tubes offer a more efficient cross-section for load-bearing structures than round pipes, making them a preferred choice in both architectural and industrial design.

Common Uses of Square & Rectangular Steel Pipes

These hollow steel sections are used in a wide variety of applications:

-

Construction: Steel frames, columns, bridges, warehouses, and prefab buildings.

-

Furniture: Frames for office chairs, tables, shelves, and metal beds.

-

Agricultural Equipment: Structures for sheds, machinery frameworks, and irrigation systems.

-

Transportation: Bus frames, truck bodies, and rail systems.

-

Fencing and Guardrails: Durable and long-lasting material for barriers and safety installations.

Material Grades and Standards

Both hot-rolled strip coils and hollow section pipes are available in different grades based on national and international standards such as ASTM, EN, DIN, JIS, and ISO.

-

ASTM A36, A1011 – Common standards for hot-rolled coils.

-

ASTM A500, A513 – For cold-formed welded and seamless carbon steel structural tubing.

-

EN 10210 / EN 10219 – European standards for structural hollow sections.

These materials are available in various thicknesses, widths, and lengths depending on project requirements.

Why Choose Midwest and Asian Suppliers?

When sourcing hot-rolled steel strip coils or rectangular and square steel pipes, manufacturers in Asia (especially China, India, and South Korea) are known for competitive prices, high production capacity, and wide export networks.

On the other hand, Midwest steel suppliers in the United States offer:

-

High quality control and traceability

-

Fast domestic delivery

-

Reliable after-sales service

-

Compliance with US building codes

For companies operating across North America, working with Midwest-based manufacturers or distributors ensures access to premium-grade steel with the reliability of local service and timely supply.

Tips for Choosing the Right Steel Supplier

To ensure quality and efficiency in your steel projects, consider the following when selecting a supplier:

-

Grade availability: Can they provide the steel grade you need?

-

Customization options: Do they offer cutting, slitting, bending, or galvanizing?

-

Production capacity: Can they handle bulk or urgent orders?

-

Certifications: Look for ISO, ASTM, and other relevant quality certifications.

-

Pricing and logistics: Balance cost savings with delivery times and service quality.

Conclusion

Hot-rolled steel strip coils and square/rectangular steel pipes are essential components in industrial, commercial, and structural engineering. Their strength, adaptability, and economic value make them a first-choice material for everything from skyscrapers to buses and machinery.

Whether you’re sourcing from global manufacturers in Asia or trusted Midwest suppliers, choosing the right grade and format ensures long-term performance, safety, and efficiency.

If you’re seeking reliable supply, cost savings, and superior quality, investing in these steel products from a certified manufacturer or wholesaler is a smart move for any project.