Cold Rolled Strip Coil – Midwest Steel Supply Solutions

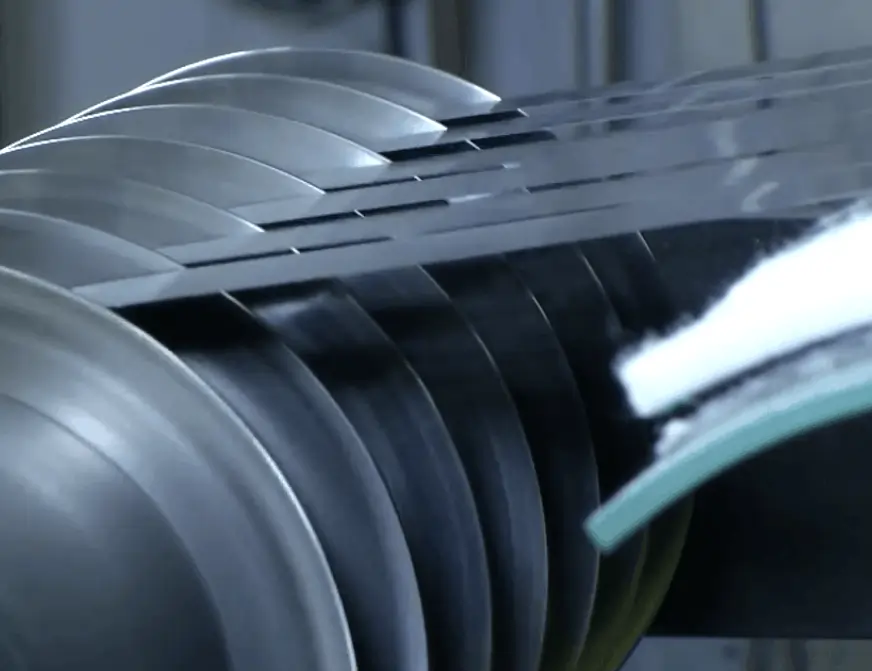

Cold rolled strip coil is one of the most widely used steel products across manufacturing, construction, and fabrication industries. Known for its smooth surface finish, precise dimensions, and excellent mechanical properties, cold rolled steel strip coil plays a vital role in producing high-quality components. Midwest steel supply companies are recognized for delivering reliable cold rolled strip coils that meet the needs of diverse industries throughout the United States.

This article explores what cold rolled strip coil is, its manufacturing process, key features, applications, and why Midwest steel suppliers are a preferred choice for sourcing this material.

What Is Cold Rolled Strip Coil?

Cold rolled strip coil is a flat steel product produced by rolling hot rolled steel through rollers at room temperature. This cold rolling process reduces thickness, improves surface quality, and enhances mechanical strength. The steel is then coiled for easy handling, transportation, and processing.

Cold rolled strip coils are typically thinner than hot rolled products and offer tighter dimensional tolerances, making them ideal for precision applications.

Manufacturing Process of Cold Rolled Strip Coil

The production of cold rolled strip coil involves several controlled steps:

-

Hot Rolled Steel Pickling

Hot rolled steel is cleaned using acid pickling to remove scale and surface impurities. -

Cold Rolling

The steel passes through rollers at room temperature, reducing thickness and improving strength. -

Annealing

The steel is heat-treated to restore ductility and improve formability. -

Temper Rolling (Skin Pass)

A light rolling process improves surface finish and flatness. -

Coiling and Inspection

The finished strip is coiled and inspected for quality and dimensional accuracy.

Midwest steel suppliers use advanced equipment to ensure consistent quality throughout this process.

Key Features of Cold Rolled Strip Coil

Cold rolled strip coil offers several advantages over other steel products:

-

Smooth and clean surface finish

-

High dimensional accuracy

-

Improved tensile strength

-

Excellent flatness

-

Superior formability

-

Consistent thickness

These features make cold rolled steel strip coil suitable for demanding applications.

Common Grades of Cold Rolled Steel Strip Coil

Midwest steel supply companies typically offer a wide range of grades, including:

-

ASTM A1008 (CS, DS, DDS)

-

ASTM A366

-

SAE 1006 / 1008

-

Low carbon and high-strength grades

Different grades are selected based on strength, formability, and end-use requirements.

Applications of Cold Rolled Strip Coil

Cold rolled strip coil is used across many industries due to its versatility and performance.

Automotive Industry

-

Body panels

-

Structural components

-

Interior and exterior parts

Construction and Building

-

Metal framing

-

Roofing accessories

-

Panels and trims

Appliances and Equipment

-

Refrigerators and washing machines

-

HVAC systems

-

Electrical enclosures

Manufacturing and Fabrication

-

Precision tubing

-

Stamped parts

-

Fasteners and brackets

Why Choose Midwest Steel Supply for Cold Rolled Strip Coil?

Reliable Quality Standards

Midwest steel suppliers adhere to strict ASTM and industry standards, ensuring consistent mechanical and chemical properties.

Wide Inventory Availability

Suppliers in the Midwest maintain large inventories of cold rolled strip coil in various widths, thicknesses, and grades for fast delivery.

Custom Processing Services

Many Midwest steel supply companies offer:

-

Slitting

-

Cut-to-length

-

Leveling

-

Custom coil sizes

These services reduce production time and material waste.

Strategic Location and Fast Logistics

The Midwest’s central location allows for efficient distribution across the United States, minimizing lead times and transportation costs.

Surface Finish Options

Cold rolled strip coils are available in different surface finishes depending on application needs:

-

Matte finish

-

Bright finish

-

Oiled or dry surface

-

Special surface treatments upon request

These options enhance corrosion protection and processing performance.

Strength and Formability Balance

Cold rolled strip coil provides an ideal balance between strength and ductility. After annealing, the steel becomes easier to form while maintaining high tensile strength, making it suitable for stamping and bending operations.

Cost Efficiency and Performance

While cold rolled steel is typically more expensive than hot rolled steel, it offers better surface quality and tighter tolerances. Midwest steel suppliers help customers optimize cost by recommending the right grade and processing method for each application.

Quality Control and Testing

Midwest steel supply companies perform rigorous quality checks, including:

-

Thickness and width measurement

-

Surface inspection

-

Mechanical testing

-

Chemical analysis

This ensures every coil meets customer and industry specifications.

Sustainability and Recycling

Cold rolled steel strip coil is fully recyclable. Many Midwest steel suppliers support sustainable practices by sourcing recycled materials and reducing waste during processing.

Choosing the Right Cold Rolled Strip Coil Supplier

When selecting a Midwest steel supplier, consider:

-

Product range and inventory

-

Processing capabilities

-

Certifications and quality standards

-

Delivery reliability

-

Technical support

A trusted supplier ensures consistent material performance and long-term partnership value.

Conclusion

Cold rolled strip coil from Midwest steel supply companies offers precision, strength, and reliability for a wide range of industrial applications. With advanced manufacturing processes, strict quality control, and strategic distribution advantages, Midwest suppliers continue to play a key role in supporting U.S. manufacturing and construction industries.

Choosing the right cold rolled strip coil and supplier ensures improved performance, cost efficiency, and product quality across your operations.